Wholesale of industrial equipment

Are you looking for high-quality and reliable industrial equipment for your production? We have a solution for you! We offer a wide range of high-tech equipment for various industries that will help you improve the productivity, quality and efficiency of your business. By purchasing industrial equipment from us, you receive: guaranteed quality and reliability, technical support and expert advice, an individual approach to each client, competitive prices and flexible terms of cooperation. Don't put off improving your production until later - upgrade your equipment today and see how your business begins to flourish. Make the right choice in favor of high-quality industrial equipment and ensure a successful future! Contact us for consultation and selection of the most suitable solutions for your business.

Milling machines

A milling machine is a universal industrial equipment that is used to process various materials by removing material using a rotating tool - a milling cutter. The milling machine is widely used in mechanical engineering, metalworking, tool production, as well as in other areas of industry.

More products

Drill presses

Drill press, also known as a drilling machine or a pillar drill, is a machine tool used for drilling holes in various materials such as wood, metal, plastic, and other workpieces. It consists of a base, column, spindle, drill head, and a worktable.

More products

Horizontal Metal-Cutting Bandsaws

Drill press, also known as a drilling machine or a pillar drill, is a machine tool used for drilling holes in various materials such as wood, metal, plastic, and other workpieces. It consists of a base, column, spindle, drill head, and a worktable.

More products

Surface Grinders

Surface grinders are precision machine tools used for grinding and smoothing the surface of workpieces to achieve a high level of flatness, parallelism, and surface finish. They are commonly used in metalworking, tool and die making, and other industries where precision surface finishing is essential.

Metal Lathes

Metal lathes are versatile machine tools used in metalworking to shape, cut, and manipulate metal workpieces by rotating them along their axis while various cutting tools are applied to remove material. Metal lathes are essential in manufacturing, machining, and metal fabrication industries for creating a wide range of precision components.

More products

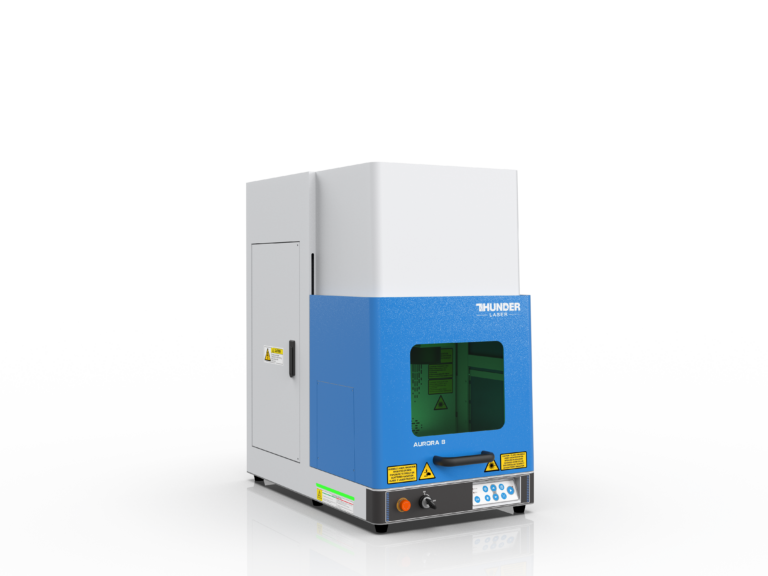

Laser cutters

Laser cutters are advanced machine tools that use a high-powered laser beam to cut, engrave, and etch various materials with precision and accuracy. These versatile cutting machines are widely used in industries such as manufacturing, aerospace, automotive, signage, and crafts for creating intricate designs, prototypes, and customized components.

More products

If you have any questions, or your product is not in stock, please contact us at any time and our specialists will contact you as soon as possible.